Product > Valuable parts > Primary catalyst unit |

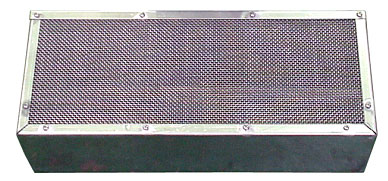

Primary catalyst unit

|

| Primary catalyst unit |

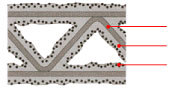

| Enlarged cross-sectional view of metal honeycomb catalyst | |

|

Structural support |

| Wash-coat | |

| Catalytic active material | |

|

|

This Catalyst unit is to purify exhaust gas which is occurring while making enamel wire. Excellent purifying performances with very low pressure drop. |

|

||||||||

|

||||||||

| Model | Primary catalyst unit (suing a cubic type metal honeycomb catalyst) |

| Material | Structural support: stainless steel wheel (Fe-20Cr-5Al) Wash-coat: γ-alumina (rare earth element of stable type) Catalytic active material: Pt |

| Dimensions | Differ depending upon models Catalyst cell density: 260 CPSI (cells per square inch) |

| Appropriate operating temperature | To obtain specified purification performance: min. 300℃ To maintain specified catalyzing performance: below 800℃ |

| Purification characteristics | Surface-supported type catalyst having very large surface area and highly active purifying performance due to the catalytic precious metals existing on catalytic surfaces. (See graph 1.) |

| Pressure loss | Use of 50µm-thin plate realizes a very small pressure loss. (See graph 2.) |

| Thermal conductivity and thermal capacity | Use of stainless steel structural support brings about high thermal conductivity and low thermal capacity, thus making it possible to achieve very quick temperature rise to the catalyst operating temperature. |

| Mechanical strength | Strong against vibration, heavy load, and physical and thermal shocks (caused by sudden change of temperature). |

| Maintenance | Cleaning with neutral detergent allows normal performance and long life to be maintained. |

Product > Valuable parts > Primary catalyst unit |